Lineman…they have one of the most dangerous jobs in the world. Extensive training and having the safest equipment possible is a top priority for the lineman of the IBEW. And that is where Salisbury by Honeywell come in with their state of the art lineman gloves. Their eight-step process ensures that all gloves that end up on the job site are dependable, safe, and worthy of the IBEW lineman.

Let’s take a deep dive into the process of how these gloves are made by going to the source. Charleston, South Carolina at the Salisbury by Honeywell factory!

To download this video, click here!

—

Transcript: Lineman Gloves and How They Are Made

Hi, I’m Matthew Walton, for lineman they rely on tools and equipment to keep them safe and get the job done. And one of those products is made right here in Charleston, South Carolina. We brought our cameras in to see first hand how the gloves are made.”

At Salisbury by Honeywell, there are eight steps in the process to make the perfect lineman’s glove.

Let’s see how it’s done. Let’s meet the people that make it happen.

Step 1: Mix Incoming Rubber and Verify Viscosity

When the rubber comes in, samples are taken back to the lab for approval. Once approved, they are taken to the staging area. Trucks are loaded with the rubber and on to the mixing room.

Charles Edwards – Mixing Lead “The first thing we do is add the solvent to the mix. We have single and triple batches so it’s 270 gallons for single and 810 for a triple batch. Once the solvent is added we take the trucks to the appropriate room.”

After a 24-hour process of mixing, the rubber is sampled.

Charles Edwards – Mixing Lead “After we get the sample we sample the viscosity of the mixers. That tells us whether we need to add more solvent to bring it down to our target. We keep doing that until we get our target. We might do it two or three times.

Step 2: The Dipping Process

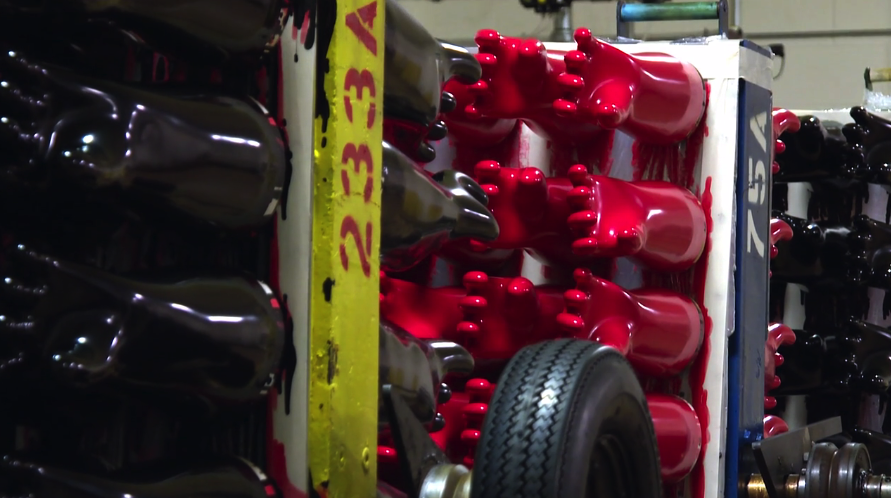

Once the rubber meets the correct specifications, it is filtered and transferred to the dipping tanks. The dipping process is tightly monitored for quality control purposes. Double-sided racks of porcelain hand forms are utilized to maximize production capacity. The overall dipping process can take up to several days for some gloves depending on the voltage class of the glove being produced.

Step 3: Autoclave and Stripping

Matt Harwell – Production Supervisor “After the gloves are dipped they come out and they are rolled, then they get their serial number then are rolled to correct length whether it’s 16 or 18 inches. Then they go to the autoclave, which is 260 degrees anywhere from 25 to 45 minutes. That uses pressure and steam to help cure the gloves. Instead of it being a gummy substance it goes to rubber.”

Once the gloves come out of the autoclave they are stripped from the porcelain form. The gloves are now ready for chlorination and the porcelain forms are cleaned and readied to go for another dip.

Step 4: Chlorination

Reggie Bird – Senior Electrical Engineer “After the gloves comes from stripping they are very rough in nature. If you tried to stick your hand in the glove it would literally pull the skin off your hand it’s so rough. It hasn’t been made smooth yet. So basically we give it a chlorine bath, we have a big bath where we mix bleach and acid together and by doing that we are able to release the free molecule from the bleach.”

Matt Harwell – Production Supervisor “Everything we do here as far as quality is 100 percent inspected. We don’t catch everything we can in our department but there are so many tiers of quality control that nothing escapes.”

Step 5: Visual Inspection

There are six different classes of gloves. When they come into the inspection process the operator will randomly grab three gloves.

They make sure they are in thickness specification and visual. They set them up on the micrometer to make sure they are right.

Step 6: Dielectric Testing

Barry Moddelton – Quality Control Inspection and Testing Supervisor “You wait for the glove to fill up and there’s a probe that goes into the water that electrically charges the water. The electricity runs through the glove for a three-minute test. If there’s a weak spot in the glove it basically will have an electrical failure. It will blow a hole into the glove and that glove is deemed bad it’s cut and deemed not serviceable.”

Step 7: Packaging

Michael Kinneary – Materials Manager “This is the stock and control in this area we pare the product left and right, count the product, we report the production and order it prior to putting in boxes and then put it into inventory. Stock control is the last line of defense for quality to the customer. We make sure we have a left and a right glove, the correct size, we pare them up and put them in the box and make sure the correct label goes on the box. Everybody in this department takes pride in their job. We take pride in the fact that we are protecting lives throughout the world.”

Step 8: QC Lab Testing

Cynthia Bryant – QC Department, Tester “My job is important because I test the gloves to make sure there are no holes in them and that helps us save lives when there’s no holes in them. We do dialectical testing. The higher the class the more voltage you have to put into the glove. I take very pride in my job because by me testing these gloves to make sure they are good that helps me save someone who is using these gloves out in the field.”

So the next time you put on a pair of Salisbury Gloves, know that the people who make them care just as much as you do about your safety. For IBEW Hour Power, I’m Matthew Walton.

(3007 views)