As the IBEW has seen in recent years, the population growth of the United States has lead to many commercial and residential electrical projects in order to accommodate for the growth.

What the population boom has also done is caused an increase in traffic! In order to provide a solution to the traffic problems in the Elizabeth River area, IBEW Local 80 is working on the new Elizabeth River Tunnels, the roadway from Norfolk to Portsmouth.

Watch this feature now to learn more about the IBEWs role in this incredible project!

To download this video, click here!

—

Transcript: Elizabeth River Tunnels Project

Welcome to Norfolk Virginia, an area of the country that is rich in history and scenic beauty. And with a sticker price of $2.1 billion, Norfolk is also home to one of the largest construction projects in the U.S.

billion, Norfolk is also home to one of the largest construction projects in the U.S.

The Elizabeth tunnel river project has been a top priority for the Hampton Roads region for many years. The Elizabeth river separates the cities of Portsmouth and Norfolk that is home to 1.7 million people and it’s home to the world’s largest navel base and several marine terminals.

Over the years the region’s population has increased nearly 70% and tunnel usage has gone up by nearly 600%! So, when the existing tunnel and surrounding highway infrastructure could no longer handle growing traffic (6 times greater than it used to be) the Virginia Department of Transportation called on the men and women of IBEW Local 80 to help build the Elizabeth River Tunnels Project.

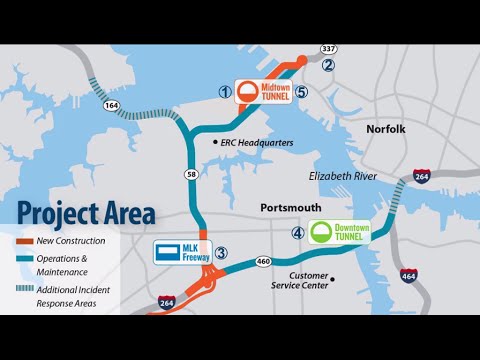

The project is broken into five elements: a new midtown tunnel, the Norfolk Approach, the Martin Luther King Freeway Extension, rehabilitation of the existing downtown tunnel, and rehabilitation of the existing midtown tunnel. When it is complete the average round-trip commute will save about 30 minutes a day. It all translates into broad and lasting benefits to the economy and the lives of those who live and work in the region every day.

With this much work the Elizabeth River Tunnels team had specific goals they wanted to accomplish before construction started; among them was to hire the best skilled local labor.

Daniel Francis: Project Manager, SKW Instructors “I am from this area so I think it’s very important that we hire locally in the Hampton roads area. It is very important for us to hire local.

Daniel Francis: Project Manager, SKW Instructors “I am from this area so I think it’s very important that we hire locally in the Hampton roads area. It is very important for us to hire local.

Susan Ritter: President, Bryant Ritter Hewitt Electric “This project is a highly technical complex project and not just any company can step in and do this. That’s why we are lucky to have Local 80.

Susan Ritter: President, Bryant Ritter Hewitt Electric “They are top notch, top quality, we hear all the time from members out here on the site what a great job they are doing.”

And what is the benefit of hiring local?

Randall Hewitt, Vice President Hewitt Electric “This project we have been able to hire local we have grown from 15 to over 50 men and it has helped our company grow in general.”

Daniel Francis: Project Manager, SKW Instructors “We have had up to 700 people working here on site, and we break it down to the crew level so we know where each person is going.”

Working with that many trades people, and at a point 90 feet under the surface of the water, this project has some unique challenges.

Shawn Bruce: Superintendent, MASS Electric “There are a bunch of items we still need to try to complete in the roadway like devises, RLS signs everything like that It gets to be challenging when the have concrete trucks coming in and out. They’re still building the tunnel and we are trying to complete it on the back end.”

Shawn Bruce: Superintendent, MASS Electric “There are a bunch of items we still need to try to complete in the roadway like devises, RLS signs everything like that It gets to be challenging when the have concrete trucks coming in and out. They’re still building the tunnel and we are trying to complete it on the back end.”

Shawn Bruce: Superintendent, MASS Electric “With Champion and what they have done with the fiberglass conduit, they have helped us out and shown us different things we can do. We have asked them to bend some offsets for us and they have come out fabulous. We are able to do some in field bends with heat blankets. There is a learning curve but overall I’m proud of what the guys have done.”

Joshua McCoy: Journeyman, IBEW Local 80 “As far as the pipe, getting the pipe straight so everything is in line going down straight and the signs need to be oriented perfect for traffic so they can see which way they are going. Just little things that the public may not see but as an electrician somebody is going to come through and see.”

Adam Tatem: 5th Year Apprentice, IBEW Local 80 “It’s tough, you have to bend all this conduit. The best thing is  though that you have people that can teach you. They have already given us a lesson on how to do it and what not to do and what settings it should be on. We had hands on training.”

though that you have people that can teach you. They have already given us a lesson on how to do it and what not to do and what settings it should be on. We had hands on training.”

When done, the men and women of IBEW Local 80 will have installed over 340,000 ft. of conduit, pulled close to 2 million ft. of wire, and installed over 1,400 lighting fixtures.

Kyle Hewitt: Journeyman, IBEW Local 80 “It is one thing as union members pride ourselves on is quality in craftsmanship. It is an awesome project. It is not to often you get to work on a tunnel.”

Shawn Bruce: Superintendent, MASS Electric “If I had to give the members a grade as far as quality and production, I would give them an A.”

For IBEW Hour Power, I’m Matthew Walton.

(2258 views)