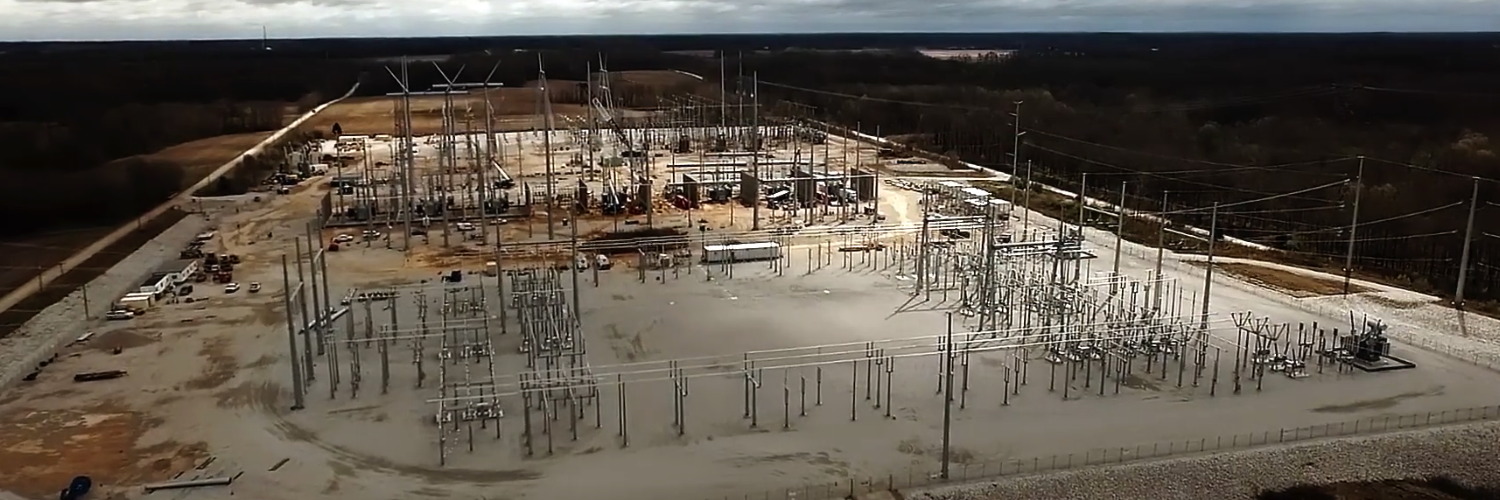

In today’s world of aging infrastructure, how the grid is managed and maintained – from the power station to a switch on your wall – has never been more important! Although substations may not seem sexy, they are a crucial piece to life as we know it. The Indiana Substation is one of the largest substations in America which the IBEW has taken the chance to rebuild!

To download this video, click here!

Welcome to another edition of IBEW Hour Power, we are here in Fairbanks Indiana watching the IBEW rebuild one of the largest substations in America!

Eric Blind: Project Manager, AEP

“This is a 765 KB station project. We are rebuilding an existing station that had two that were 1960’s vintage equipment so they were getting to the end of their life cycle and adding a third bank of 765 transformers.”

That third bank addition means seven brand new transformers that will do double the capacity for future system demands. The project is a 60 million dollar investment for American Electric Power and it is vital that it will be done right for the first time.

Thomas Householder: Managing Director of Labor Relations, AEP

“This project is in a very isolated area. Getting skilled craft labor is very challenging. It’s critical that a job of this technical complexity to have people that have done it before have the capability to do it. The main reason we picked the IBEW is because they are safe. They are very well trained and capable.”

This isn’t the first time AEP, New Kirk Electric, and IBEW Locals 876 and 1393 have worked together.

Randy Gardner: Assistant Business Agent, IBEW Local 1393

“The local and the contractors have to have a great relationship. If we don’t, we are all going to fail. The camaraderie between us, the contractor and the local is great. We have a great working relationship.”

Travis Kamps: General Foreman, IBEW Local 876

“We built a 345 yard and we added a bay onto the 765 yard and now we are building the transformer yard to tie the two together. Hanging drops, welding, building containment pits for the oil and transformers, building steel today and hanging stag wire.”

Dustin Eads: 1st Year Apprentice, IBEW Local 1393

“We are in the middle of an outage right now so we are working long hours, all conditions but there’s a great variety of work and so far it’s been going really good.”

Tyler Pierson: 1st Year Apprentice, IBEW Local 1393

“Today we are just hanging drops and jumpers on the station service. All the guys out here are here to help and no one out here wants to do you wrong. They are out here to help every day.”

Working outside is just one of the many factors that can leave an electrical professional in an ever changing work environment.

Travis Kamps: General Foreman, IBEW Local 876

“Some of the challenges we faced particularly down here is weather. MUD! At one point we were in mud up to our knees every day for two months in that 345 yard.”

Mark Tietbohl: Safety Representative, New Kirk Electric

“Slip hazards because of the mud, it’s a clayish material and it does get slippy. When it was snowing we bought ice cleats for the guys to wear while really helped in this material. Safety is the priority, production second. Safety is the priority.”

Travis Kamps: General Foreman, IBEW Local 876

“This is a large job site, 39 acres, in order to guys and tools around we rent carts and gators to bring people back and forth. One of the largest sites I’ve ever been on.”

Though the work can be complex…the reasoning behind it all is simple.

Eric Blind: Project Manager, AEP

“Our end goal is to get a modernized infrastructure in place in the transmission grids so we can provide safe, reliable electricity to our customers at an affordable cost.”

Reporting from Fairbanks, Indiana for IBEW Hour Power – I’m Erica McClaugherty.

(2466 views)